In this Digital Demo, Sam Cruz, MVP's Senior Product Manager, talks about how to convert from hand lay-up process to spraying fiberglass and offers an overview of the benefits. (Sponsored)

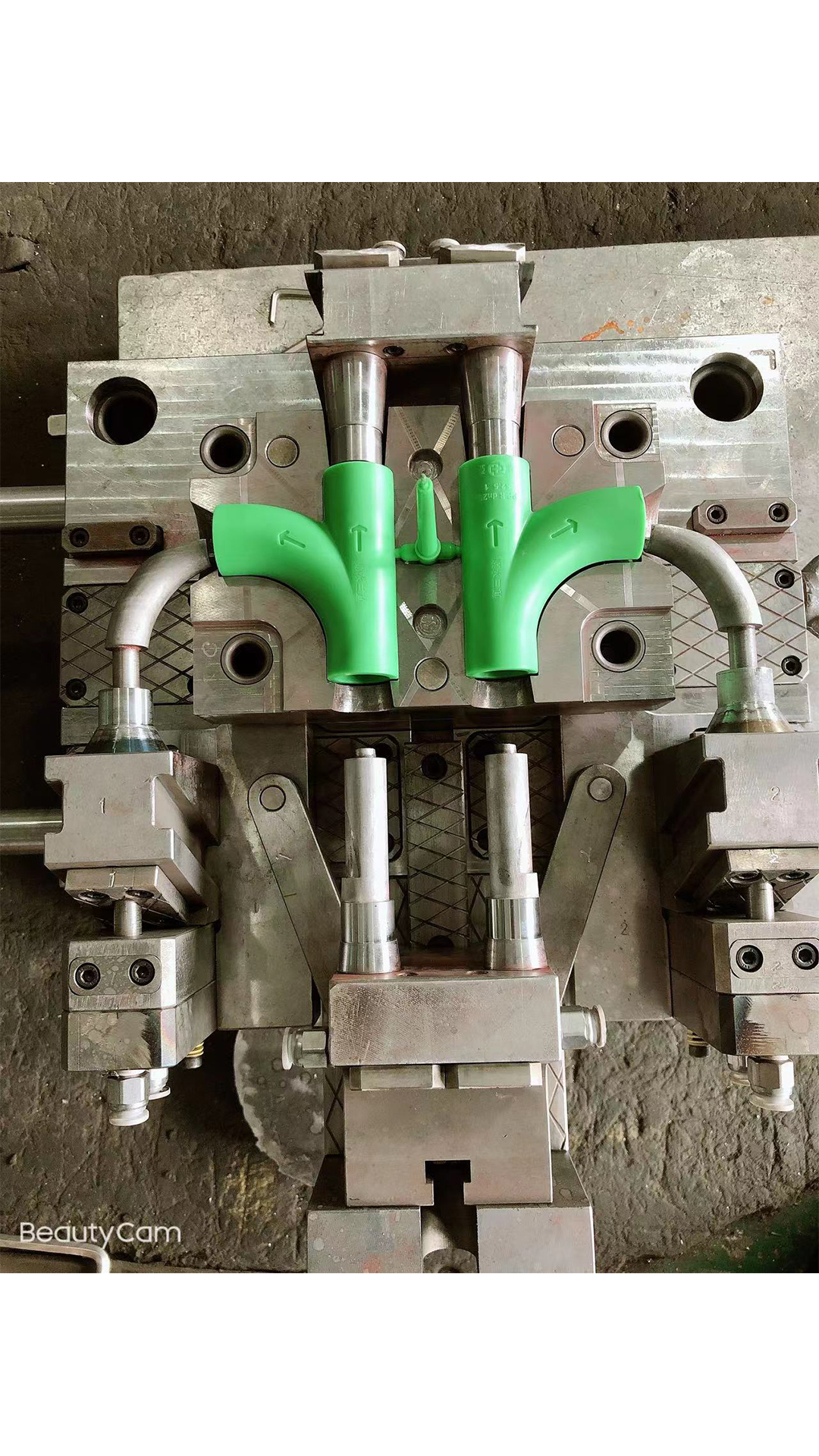

The demo gives a brief history of MVP focusing on the types of scalable solutions it provides for manufacturers. Cruz explains the importance of selecting the right equipment and processes for your unique production needs. He breaks down the spray up process, step by step, offering tips and tricks. Specific features of MVP’s systems are highlighted throughout the presentation as ways to eliminate common problems in the hand layup method. Cruz also reviews how to accurately monitor your material usage to reduce material waste and produce consistent, high-quality parts. Three Plate Mould

MVP offers a variety of chop/wet-out systems which can be tailored to your production needs for low, standard, and high-volume outputs. These systems are designed with quality parts to reduce overspray and material waste. The key to efficient FRP production is achieving a uniform laminate, and precise metering will correct many of the most common quality issues, such as porosity and inconsistent thickness. Leverage MVP’s experts for advice and knowledge to formulate the right production solution for you.

For more information on this and other MVP products, visit mvpind.com and follow them online on Facebook, Twitter and LinkedIn.

Well-known in structural applications, this symmetric, balanced and quasi-isotropic fabric offers savings and opens opportunities in composites tooling.

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

Subscale 5.5m-diameter cryogenic tank demonstrator with innovative fluted-core skirt is formed via robotic AFP and cured out of the autoclave.

Three Plate Mould © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]